Neumünster - Oerlikon Nonwoven will be presenting its product portfolio for nonwovens applications for numerous technical, hygiene and medical solutions focusing on sustainability, quality and efficiency at next month's INDEX exhibition.

Visitors will be able to meet the company's nonwovens experts at both 2314, allowing them a closer look at the hycuTEC charging unit, the current holder of the Filtrex Innovation Award, amongst other things.

“When developing our technologies, we not only focus on system efficiency and product quality, but also on sustainability, energy efficiency and preserving resources,” explained Dr. Ingo Mählmann, vice president Sales & Marketing at Oerlikon Nonwoven, adding that the company's declared objective was to be the leading partner for manufacturing sustainable and environmentally-friendly solutions in the nonwovens industry. “There are many future-oriented bio-based and biodegradable polymers that can be used to produce nonwovens. Here, we want to support our customers in becoming pioneers in processing such polymers.”

Alternatives to the standard polymers widespread today are required and Oerlikon Nonwoven says it is able to offer the competence and the technologies for processing these new polymers.

Bio-based polylactic acid

The bio-based polymer PLA (polylactic acid) may be an alternative for those wanting to manufacture sustainable nonwovens. The Oerlikon Nonwoven meltblown and spunbond technologies are ideally suited for processing PLA, for example. At INDEX, the company will be showcasing a sample application: medical oronasal masks manufactured entirely from PLA nonwovens.

hycuTEC

In the case of its hycuTEC hydro-charging solution, winner of the Filtrex Innovation Award 2022, Oerlikon Nonwoven offers a technology for the efficient and simultaneously energy-saving charging of meltblown nonwovens. This enables the filter efficiency to be increased to more than 99.99%.

This innovative technology is able to dispense with an additional drying process when manufacturing most highly-separating electret filter media, allowing considerable savings in the consumption of water and, above all, the energy required for drying. In turn, this ensures very low energy consumption both in the manufacturing process itself and across the entire lifespan of the hycuTEC filter media – used in ventilation and air-conditioning equipment, for example. Furthermore, meltblown producers are able to achieve potential raw material savings of around 30% as a result of the improved efficiency of the media. In other words: the same or even superior performance for lower media running meter weights. As a result, the hycuTEC technology is a particularly future-proof, resource-friendly technology.

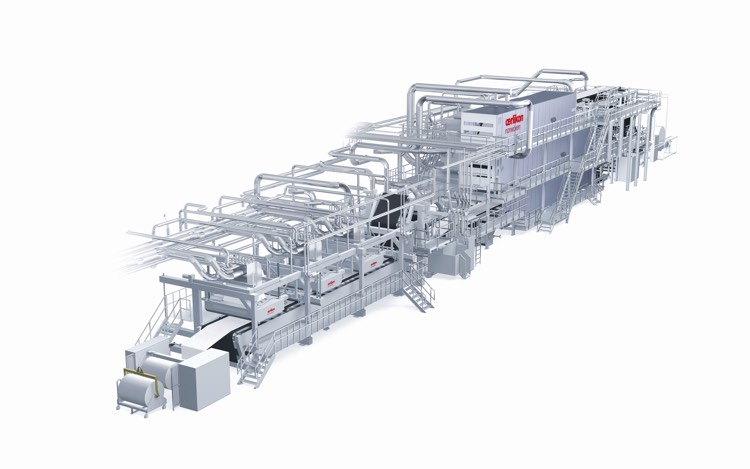

Phantom

With its Phantom technology, Oerlikon Nonwoven offers an innovative co-form technology for manufacturing wipes – including wet wipes made from pulp and polymer fibers, for instance. Here, the properties of pulp and polymer are combined in a manner that perfectly unites the properties of the starting materials.

The material mix can comprise up to 90% cellulose fibres while choosing a bio-based and biodegradable polymer enables the entire wipe to be manufactured in a ‘plastic-free’, and hence environmentally-friendly, manner.

Compared to conventional processes such as spunlace (hydroentangled carded nonwovens), the patented Phantom technology offers ecological, performance and cost advantages both in the application and in the manufacture: dispensing with hydroentanglement renders subsequent drying of the material redundant, therefore saving on the energy required for drying. Product parameters, such as softness, tenacity, dirt absorption and liquid absorption, can be optimized by means of the recipe and the process settings. The Phantom technology enables the manufacture of both flexible and absorbent structures and highly-textured materials.

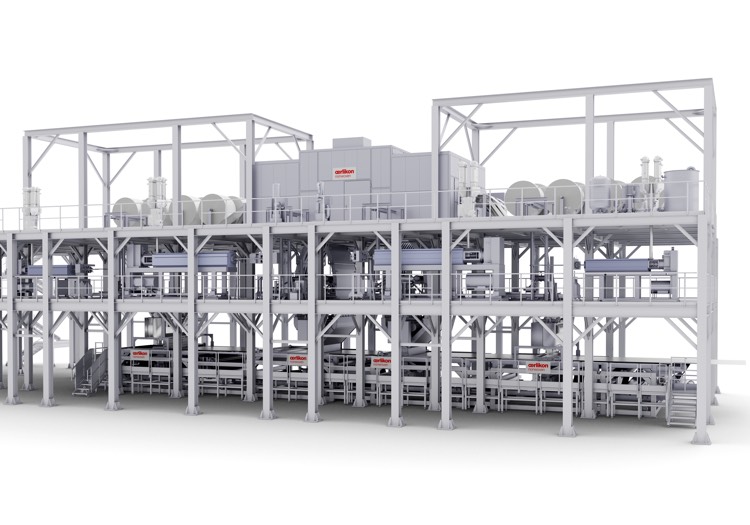

Airlaid

According to Oerlikon, pulp or cellulose fibres as raw material for manufacturing nonwovens are currently virtually unrivaled with regards to sustainability and environmental compatibility.

The Oerlikon Nonwoven airlaid process is the ideal solution for processing this raw material into high-end products for a wide range of applications. Today, there is huge demand for manufacturing solutions for high-quality, lightweight airlaid nonwovens with economically-attractive production speeds and system throughputs.

Here, the patented Oerlikon Nonwoven formation process, which has proven itself in numerous production systems, is setting standards – for homogeneous fibre laying and superb evenness even for nonwovens with low running metre weights. Whether as a system exclusively for airlaid nonwovens or combined with other nonwoven processes, the benefits of the Oerlikon Nonwoven airlaid technology are today already being deployed in numerous applications, the company says.