GENEVA – The nonwovens industry continues to push at the barriers of what is materially and technically possible in pursuit of ever-more sustainable and competitive products.

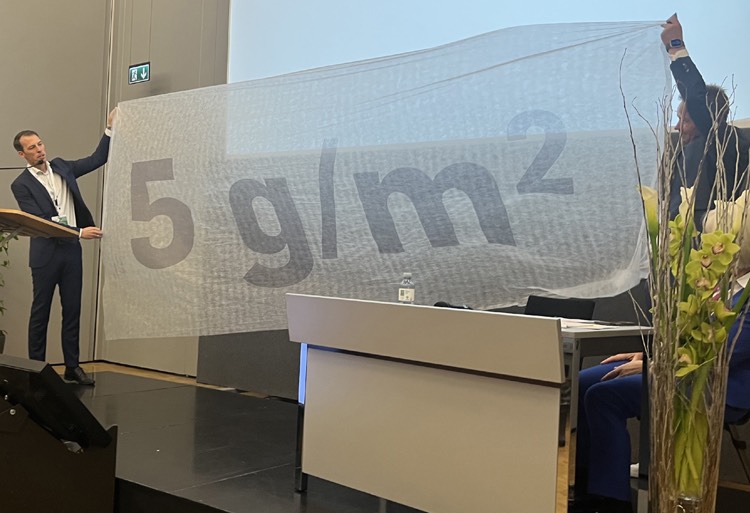

At between five and seven grams per square metre (5-7gsm), the new spunbonded nonwovens being developed by Fibertex Personal Care and introduced at the INDEX 2023 exhibition in Geneva certainly represent an extreme new example of this.

Intended for diaper backsheet and core-wrap applications, the wafer-thin and extremely delicate materials are made possible by the highly automised materials handling systems to be found in the most modern nonwovens manufacturing systems. They are also intended to be run through the complex and extremely long converting machines that are employed to make multiple-component diapers which suggests almost zero margin for error.

Limits

Around ten years ago, the basis weight of fabrics for specific components was thought to have reached its lower limits at around 10gsm, but now it appears, working with strict tension control at low machine throughputs, it’s possible to go further and still achieve the necessary performance characteristics of the nonwoven.

Explaining the rationale behind the new development during a presentation at INDEX 2023, sales director Kim Høgild Høgaard said that Fibertex Personal Care has an annual capacity of 50,000 tons of spunmelt fabrics at its plant in Denmark, and a 100,000 tons at its plant in Malaysia, all produced on the advanced Reicofil systems.

The company is among the world’s ten largest manufacturers of nonwovens for personal care, with a global market share of over 5% and sales in 2022 of €330 million.

Looking internally at the GHG emissions of its spunmelt production, the company has ascertained that just 9% of GHGs generated at the Danish plant are accounted for by energy usage and 91% by polymer raw materials, so there is little scope for making further reductions in energy efficiency. At the Malaysia plant, the situation is rather different, with 29% of GHGs generated in production and 71% by polymer raw materials.

Meanwhile, plastic production overall in 2021 was over 390 million tons in 2021, according to figures quoted from Plastics Europe, and is forecast to double by 2050 based on the latest projections.

“Only 5.9 million tons of this production was based on bio-based plastics, with 32.5 million tons from post-consumer recycled plastics in 2021, and since the raw materials we employ only represent a small percentage of our emissions, looking to make a big change with new raw materials doesn’t seem like the way to go,” Høgaard said. “Meanwhile, the lowest basis weights for these applications came down from around 17gsm in 2000 to 15gsm in 2010, but haven’t decreased much since, so we believe this is the way forward.”

“In the production of these extremely lightweight sheets, the tensiles go down but with good tension control we can improve the lay-down for good processability,” said R&D director Brian Undengaard. “The trick is in low throughput.

“In the past, production has always been about maximising the speed of the lines and we have only talked about tonnages achieved, but things need to be considered in terms of square metres.”

Benefits

As a direct comparison of 10gsm and 5gsm products, the benefits are very apparent, with more linear loading per container. Rolls of 10gsm materials that are 26,500 metres long, can be increased by almost 100% to 54,000 metres, resulting in less shipping, warehousing and material waste.

Ultimately, this results in a lower overall carbon foot print and lower costs.

When extended to the overall market of around two million tons for these components, the potential savings are a staggering:

- 555,000 metres of spunbond nonwovens, or 900,000 tons of CO2 eqv.

- 46,000 less container loads of product

“This is not a ‘plug and play’ solution, and materials handling is not easy, with close collaboration required all along the supply chain,” Undengaard said in conclusion. “Trials with converting partners are ongoing, but the first applications are close to commercialisation and the potential benefits are too big to be ignored.”