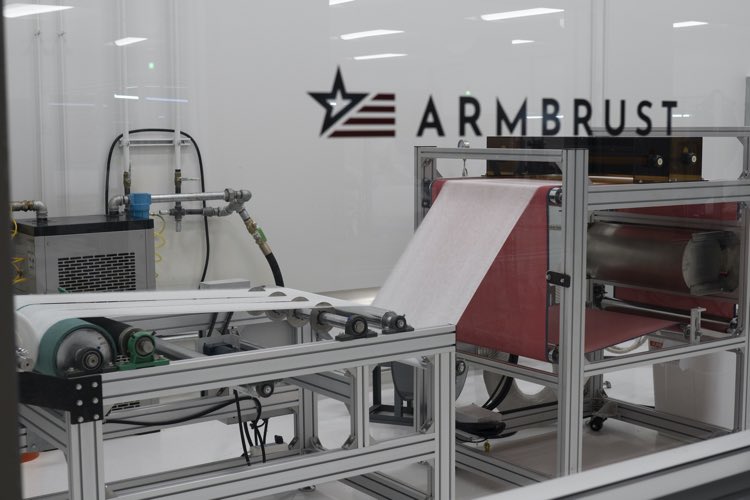

AUSTIN - Armbrust American has announced that its facilities are now capable of producing meltblown fabric, giving the company full supply chain control for the production of surgical and N95 facemasks.

Armbrust is manufacturing a new Electrostatic Armor Meltblown, the company's new proprietary blend of meltblown filtration material that more easily adds a static charge and allows those wearing a mask greater breathability.

Company founder and CEO Lloyd Armbrust said the move to produce its own meltblown would allow Armbrust American to control costs and better scale its operations so that America's first responders have the protection they need. "Nine months into this pandemic, a lack of domestic manufacturing is the only explanation for why America still does not have enough PPE," he said. "Investing to produce our own meltblown means we aren't dependent on other countries."

The majority of meltblown material is currently manufactured in China and sold to U.S. manufacturers. This, said Armbrust, has caused prices for PPE to skyrocket, with some health service providers now passing those expenses to patients in the form of surcharges, according to recent reports.