EBERBACH - Dilo Group has strengthened its position in the supply of complete hydroentanglement lines following an agreement with Italy's SICAM.

Dilo is a major supplier of complete lines for nonwoven fabric production and has traditionally specialized in all types of needling lines for staple fibre products as well as high-speed needlelooms for spunbond production.

A further element key of its sales program for several decades has been fibre preparation and high-speed web-forming equipment for other nonwoven technologies.

In recent years though, notes Dilo, there has been a shift to higher throughput rates, and in some cases in Asia, a requirement for improved MD/CD strength ratios of hydroentangled products. In addition, Dilo's further development of the high-speed layering principle “Hyperlayer” has made considerable progress for better CD strength through a combination of inline cards and crossline card with crosslapper.

In particular, carding machines in a working width above 3.5m up to 5.1m have been supplied by DiloSpinnbau as complete high speed carding systems, comprising two or even three cards in a line to directly feed the hydroentangling units of various suppliers.

Together with DiloTemafa, not only have high throughput rates been achieved in the fibre preparation section of the line but also dedusting filtering and air-conditioning systems have been successfully engineered and integrated.

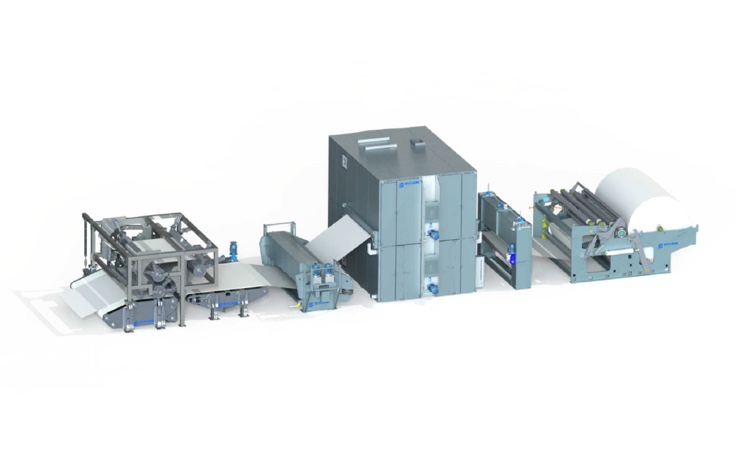

Until recently, Dilo did not supply complete lines including water-jet units, ovens and end-ofline equipment to the important hydroentanglement market segment. This position has now been remedied with the signing of a new partnership with Sicam. "Together with Sicam, we have combined know-how for hydroentangling technology and therefore can provide complete lines as general contractor including equipment for cutting, winding and packaging," Dilo said, adding that it has also recently sold a complete line for hydroentangled products in Portugal. "The market for medical and hygiene lightweight products is booming and will require more hydroentangling capacity. On the basis of our considerable fibre preparation and web-forming know-how we are looking forward to a successful cooperation with Sicam covering the market with our related activities."