FRIEDBERG - Future-proof solutions for improving quality and productivity will be the key theme for nonwovens machinery manufacturer Autefa at the upcoming Techtextil India exhibition.

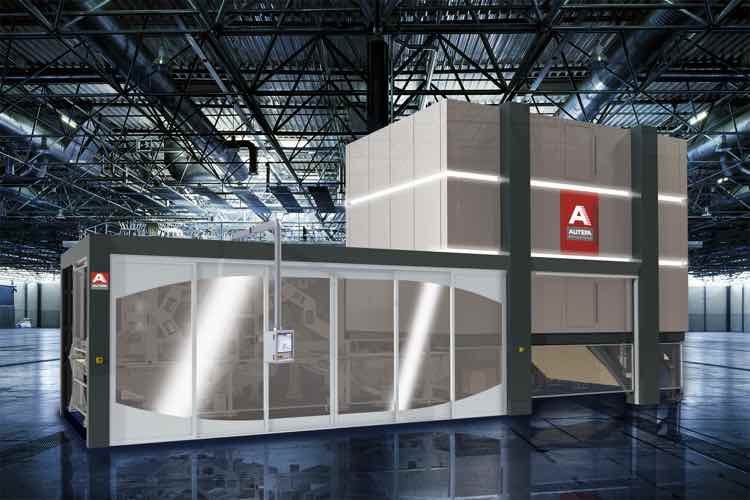

Located in Hall 4 Booth D44, the company will present its portfolio as a preferred full- line supplier for carded- crosslapped needlepunch lines, aerodynamic web forming technology, spunlace, and thermobonding lines for producing nonwoven to cater to wide range of applications such as Filtration, Geotextile, Automotive, Carpets, Technical felts, waddings, insultations, wipes and Hygiene.

In the premium nonwoven segment Autefa Solutions offers a comprehensive product range in both forming and bonding systems. With the introduction of the new Hydroentanglement Machine V- Jet Futura, for example, Autefa now offers the entire line for spunlace producers. The V-Jet injector for spunlace machines and the Square Drum Dryer SQ-V, both offer innovative contributions to energy savings and reduced manufacturing costs.

Visitors will also be able to discover the Aerodynamic Web Forming machine Airlay Futura, which, based on the successful Airlay K 12, has been very well received by the market.

Autefa Solutions says it has repeatedly introduced innovative machines, including the Crosslapper with the Closed Loop System, which influences the quality of an entire line and also raw material savings.

"Autefa lines cover the needs of the highly-competitive nonwovens market with solutions ensuring lower energy cost, lower maintenance cost combined with higher rate of production and superior quality," the company said.

A further benefit for customers is an improved and increasingly even surface quality. To meet this demand, Autefa Solutions offers a customized needle board pattern. Specifically, the i-Point needling simulation tool increases the capacity and the quality of needlepunched fabrics.

"This development of new needle patterns and the evaluation of surface quality is much more effective and economic with the i- Point software technology," says Autefa. "It creates a layout of stripper and bed plate including the elliptic needling (Variliptic). This customized design of needle pattern, which takes also draft and shrinkage into consideration, reduces the process optimization time on customer site. Autefa Solutions needlepunch lines produce an even and homogenous fabric with outstanding technical performance in terms of tensile strength and evenness (MD/CD ratio)."