EDINBURGH – At the height of the Covid-19 pandemic, some 129 billion single use face masks were being used globally each month, protecting lives while at the same time creating a new and significant plastics waste problem.

Now, a process that can degrade a common nonwoven face mask using just fresh air and 200W of electricity – about the same as a small microwave – has been developed at Heriot-Watt University in Scotland.

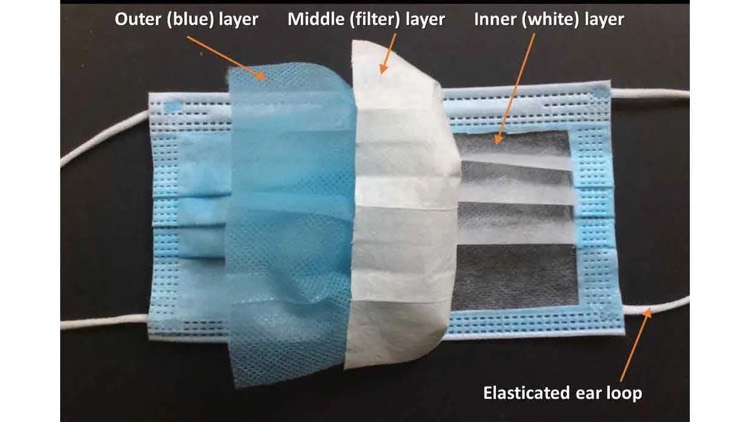

The low-power air plasma method efficiently degrades surgical masks in four hours, so that 90% of the mask is gone. It is mains-powered and produces a highly reactive environment rich in oxygen atoms that etches the plastics in the mask and eventually converts them into carbon dioxide and water.

“PPE from the healthcare sector has always been a waste challenge,” said Dr Humphrey Yiu, who led the development team. “It’s high-volume and must be treated as biohazardous waste, which means it ends up being incinerated. Incineration is expensive and not environmentally friendly – reaching the high temperatures required over a long period of time uses a lot of energy and generates a significant amount of pollutants. We have proved that our small-scale, cold plasma system can degrade single-use face masks which are still being widely used around the world.”

Professor Martin McCoustra, who specialises in complex surfaces research, added that plasma is already used to decontaminate surfaces as it destroys biological materials like bacteria and viruses as easily as any plastic.

“In this work, we’ve gone beyond simple decontamination to actually break down the waste material by exposing it to the plasma for longer and at higher applied powers,” he said.

The small-scale system, however, has limitations, with the ear loops on the masks proving extremely stubborn to degrade.

“Our focus now is on scaling up the system to prove that it could work at the hospital scale,” said Yiu. “We’d like to develop models that could be installed in hospital wards or GP practice rooms.”

The team’s findings are reported in the academic journal Materials Degradation and Dr Yiu and the team are applying for funding for the next stage of the research.