NEUMÜNSTER - Oerlikon Nonwoven premiered its new hycuTEC hydro-charging solution at the recent Filtech exhibition in Cologne.

This new technology for charging nonwovens is said to enable the filter efficiency to be increased to more than 99.99% which, as a result, provides meltblown producers with considerable material savings along with a greater filtration performance.

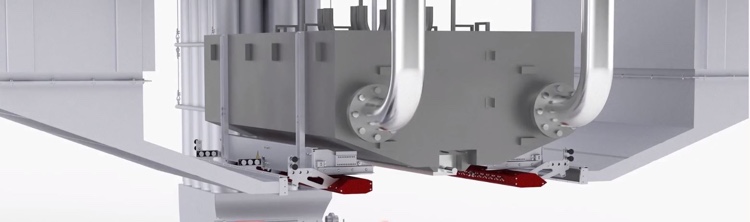

The hycuTEC is described by Oerlikon as the market’s first industrially-manufactured hydro-charging solution that can also be seamlessly integrated into the production process. It is also easily retrofitted to existing systems as a plug & produce component – a first within the market.

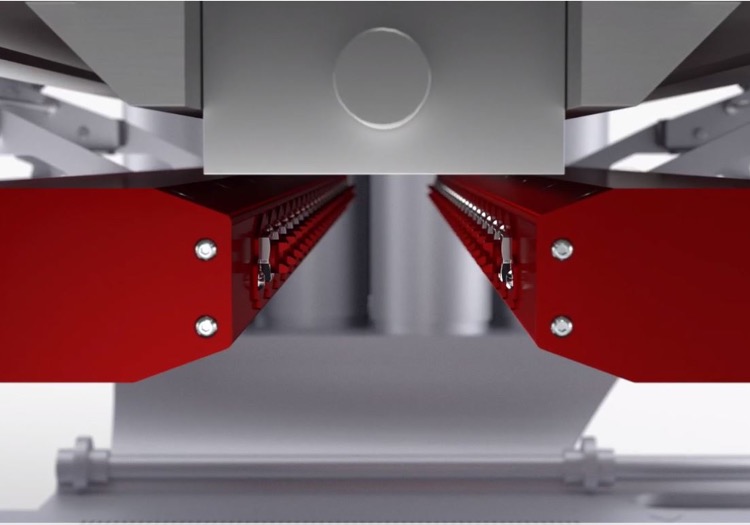

Whereas classical hydro-charging processes charge the finished nonwoven material the hycuTEC concept is based on the all-round charging of each filament. Through controlled atomization, a charge is evenly transferred to the fibres from the water spray. And a special additive is used to permanently bond the charge to the surface of each fibre. The result is filter media with a uniformly stable charge over the entire cross-section and an effective fibre surface area about 10 times greater than that of surface-charged media.

hycuTEC hydro-charging can therefore reduce the pressure loss in typical FFP2 filter media to less than a quarter. Filtration efficiencies of more than 99.99% are easily achieved in typical filter media of 35 g/m² at 35 Pa, the company says, citing tests at pilot customers manufacturing FFP2 face masks who report confirmed quality increases due to the improved filtration with a simultaneous reduction in material usage of 30%.

For end users, the consequence is noticeably improved comfort resulting from significantly reduced breathing resistance.

In addition to this, the hydro-charging unit also offers sustainability benefits. "The hycuTEC process excels as a future-proof technology due to its considerably lower water and energy consumption compared to other hydro-charging concepts," Dr. Ingo Mählmann, Head of Sales & Marketing at Oerlikon Nonwoven explains. "This unit allows an additional drying process to be dispensed with in many applications, which has a huge impact on energy consumption The hycuTEC unit can be easily and quickly installed and is simple to operate, set and service, while also being extremely user-friendly."

Integrating the new unit into a state-of-the-art Oerlikon Nonwoven meltblown system helps achieve a uniformly high product quality across the whole production process.