Autoneum has developed textile battery undercovers made of Ultra-Silent that optimally meet the specific requirements for acoustic and thermal management of electric vehicles.

With sales of electric cars picking up speed worldwide, demand for innovations that are particularly suited for this vehicle category is also growing. Components are required whose low-weight enable a greater driving range and that regulate noise levels at the same time.

With Ultra-Silent, Autoneum says it offers the most lightweight textile underbody systems; they are up to 50 per cent lighter compared with corresponding components made of plastic while they also excel with a high degree of shock resistance and optimum stone chip protection. Lightweight components made of Ultra-Silent are furthermore mostly made from recycled PET fibers that can be fully reclaimed, making them particularly environmentally-friendly.

The mono-material made of glass-free PET is resistant against water and heat and fully recyclable. It also absorbs noise and in doing so reduces vehicle noise by up to two decibels. Furthermore, Ultra-Silent underbody systems enhance the aerodynamics of vehicles by reducing their drag by up to eight per cent. This reduces fuel consumption and accordingly also CO₂ emissions.

The key factors for the electric vehicle industry are the expansion of charging infrastructure and improved driving range.

Autoneum already offers various multifunctional components such as carpet systems, inner dashes and underbody systems, which have a positive impact on the driving range thanks to their light weight and which are specially tailored to the acoustic and thermal management needs of electric vehicles.

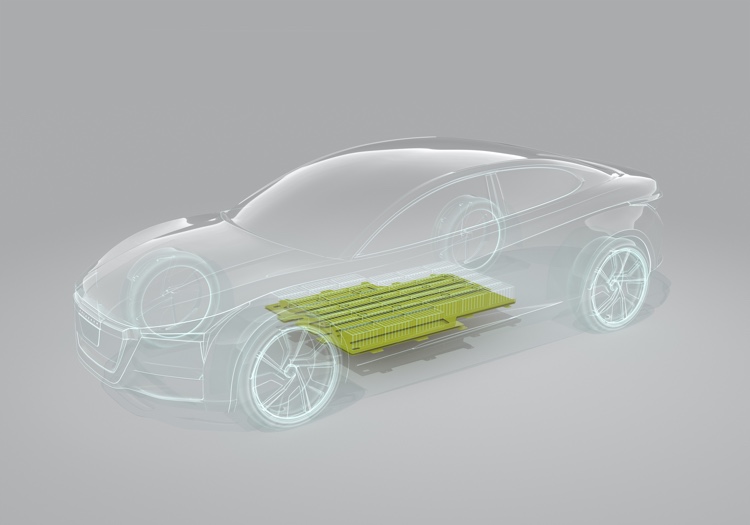

With battery undercovers made of Ultra-Silent, the company has adapted this textile underbody technology for use in electric vehicles for the first time.

The components act as insulators helping to lower sound that enters the passenger cabin, for instance caused by tires, and also pass-by noise. Sound-reducing components are essential for electric models as well because external and internal sources such as fans, pumps and electronic drive components are more audible due to the lack of engine noise and accordingly influence driving comfort.

At the same time, the textile battery undercovers also convince thanks to their low weight, therefore contributing to a greater driving range.

Undercovers made of Ultra-Silent are installed underneath the battery casing, providing the battery cells with the best possible protection against significant cooling or heating and ensuring a constant temperature with a correspondingly optimized battery capacity. As a result, the components help to improve battery performance. They are also resistant to water and vibrations and therefore help to protect the battery casing. In order to calibrate the temperature resistance and material stiffness of undercovers, Autoneum uses a broad range of internally developed simulation tools. They are deployed in both the development phase of new electric models as well as in the further development of those already on sale.

Components made of Ultra-Silent are produced in the company’s plants in Sevelen, Switzerland, Gundernhausen, Germany, Jeffersonville (Indiana), USA, and Pinghu, China, and are already in use in models of European, US and Chinese automobile manufacturers. From July 2020 onwards, the first battery undercovers will be produced in series at the Gundernhausen plant for the fully-electric model of a German premium manufacturer.