New investment during 2012 by US technical nonwovens producers is highlighting the benefits of calendering and water extraction technology from the UK’s Richard Hough Ltd (RHL).

New investment during 2012 by US technical nonwovens producers is highlighting the benefits of calendering and water extraction technology from the UK’s Richard Hough Ltd (RHL).

Significant installations so far this year have been commissioned by leading suppliers to the geotextiles and medical sectors.

RHL Syncast polyamide-covered calender rolls have been delivered for two new nonwoven geotextiles lines, one in Georgia and one in South Carolina – each operated by industry-leading companies.

Another recent contract has seen a major producer of nonwoven surgical garments purchase its second Roberto squeezing roll.

RHL has an unrivalled pedigree in the industry – the company has specialised in calender and squeeze rolls for 200 years, and in the past decade has launched a series of ground-breaking technical innovations which have dramatically improved processing efficiency and reduced both production costs and energy bills in these applications.

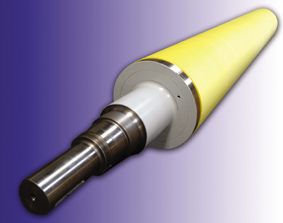

The Syncast installations in North America are both for 230-inch wide nonwovens calendering lines, each using two Syncast rolls. Made on the world’s most technically-advanced centrifugal casting machine, Syncast polyamide rolls and sleeves are based on a highly-elastic thermoplastic polymer, specially developed for textile calender rolls. They offer high performance and rapid payback, avoiding the need for a major calender rebuild. In use, the high level of elasticity guarantees minimum surface marking and shape distortion, as well as excellent runnability and maximum service life.

Roll covers of up to seven metres face length and up to 1.25 metres diameter can be supplied by RHL, making the Syncast products ideal for geotextile applications.

The latest US Roberto roll installation comes with a noteworthy endorsement from the customer, based on positive results from its original Roberto. The company, a North Carolina surgical fabric maker, is using the Roberto in the final squeeze of a 140-inch wide hydroentanglement line.

“We spent more than $70,000 on rubber back-up rolls last year,” said process manager Jimmy Avery, who manages the medical line. “Before purchasing the second Roberto, when removing the first Roberto for maintenance regrinding, we had to repeatedly interrupt a run and go to our back-up rolls, which we have no confidence in.

“The replacement Roberto roll performs great within our application and delivers the water dissipation results we need. With rubber rolls, we used 14 banks of infrared dryers, but with the Roberto we have been able to reduce this to 12 banks – with consequently substantial energy savings.”

Many thousands of Roberto rolls have been sold worldwide since their invention by Robert Oliver, of David Bentley/Modern Rollers. RHL has owned the Roberto technology since 2005, and its global success has continued as a high-performance replacement for conventional rubber or PU rolls, for efficient liquid extraction from woven, knitted and nonwoven fabrics. The Roberto uses a special microporous covering to extract the maximum liquid from the fabric – achieving 30% less residual moisture than normal rubber rolls, with consequent massive cost savings.