The BMW i8, the Volkswagen Nils and Up, the Opel Ampera and RAK e and the Smart Forvision all drew huge crowds at this year’s International Motor Show (IAA) in Frankfurt and are all based on new electromobility drive concepts.

The BMW i8, the Volkswagen Nils and Up, the Opel Ampera and RAK e and the Smart Forvision all drew huge crowds at this year’s International Motor Show (IAA) in Frankfurt and are all based on new electromobility drive concepts.

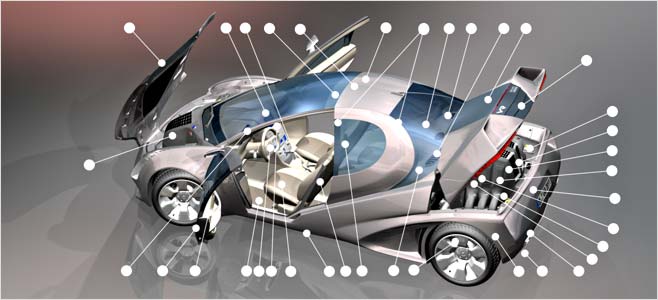

These, says German technology specialist Groz-Beckert, will lead to a rapid expansion in the use of textiles and nonwovens in vehicles – predicted to rise from 20kg per car this year to 30kg by as early as 2015.

The current state of drive technology, however, only enables conventional vehicles to be replaced by purely battery-driven models under certain conditions, the company points out.

The power only lasts for a maximum of 150 kilometres, after which the vehicle has to be recharged for several hours at a time. Many experts believe the fuel cell has more potential here. With the help of hydrogen, it generates the power for driving the electric motor – and is completely emission-free.

In addition to their ecological benefits, the new drive concepts do, however, add a considerable amount of additional weight. This means that weight has to be saved in other areas - and here, textiles are the right choice. As compound materials, such as carbon fibre, their low weight and high rigidity give them impressive performance features. They are stronger than steel and around one-third lighter than aluminium.