GENEVA - SABIC's newly formed Hygiene & Healthcare segment of its Petrochemicals business is showcasing its extensive portfolio of Purecares polypropylene (PP) and polyethylene (PE) polymers for high-purity nonwovens and hygiene films at this week's INDEX exhibition in Geneva.

The company’s exhibit at Booth 2441 is also featuring enabling solutions developed with partners to address the issue of plastic waste and support the transformation of the industry towards a circular economy with closed-loop initiatives and certified circular polymers under its Trucircle portfolio and services.

“Our new Hygiene & Healthcare market solution organization will aligns our efforts to support our customers’ needs in this industry more effectively,” says Abdullah Al-Otaibi, General Manager ETP & Market Solutions, SABIC Petrochemicals. “The new setup will drive tailored technology platforms and advanced product developments for customers who require this advanced, differentiated performance. At the same time, it will help us maintain and strengthen our competitive lead by accelerating the pace of innovation to respond to market trends more quickly.”

Highlights on display include dedicated PP and PE grades for lightweight nonwoven fabrics using the latest spunbond and meltblown processes, and a new ultra-high melt flow PP product engineered for meltblown fibers in nonwoven fabrics. The nonwoven focus is complemented by industry proven polyolefins for cast and blown film applications in hygiene webs and laminates, providing desirable back and top sheet properties such as water tightness, breathability and elasticity.

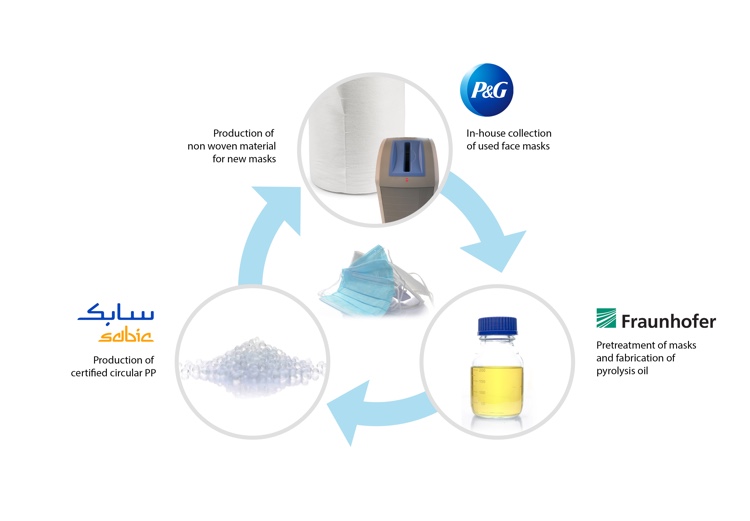

In addition, SABIC is also presenting ISCC Plus certified fiber and film polymers based on circular and renewable PP and PE polymer technology as part of the its Trucircle portfolio for advancing the transformation of the plastics industry from a linear to a circular economy. Examples of this comprehensive initiative include collaborations with various market leaders in the field. Together with Fibertex Personal Care, for example, one of the world’s largest manufacturers of spunbond nonwovens for the hygiene industry, SABIC is creating a range of high-purity nonwovens for the hygiene market using ISCC PLUS certified circular PP polymer derived from post-consumer plastic waste. In another project, Fraunhofer Institute, SABIC and Procter & Gamble (P&G) joined forces to develop and demonstrate the feasibility of an advanced close-loop recycling process for used nonwoven facemasks.