Resins specialist Dordan Manufacturing, based in Chicago, Illinois, has introduced the first thermoformed sample of the algae-plastic developed by Algix.

Resins specialist Dordan Manufacturing, based in Chicago, Illinois, has introduced the first thermoformed sample of the algae-plastic developed by Algix.

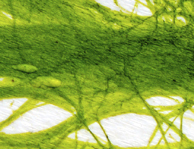

Deriving up to 70% of its feedstock from aquatic biomass obtained from nitrogen and phosphorus-rich waste-water and blended with various concentrations of PE, PP, EVA, PLA, TPS, PHA etc., the new bioresin could provide industrial manufacturers to make use of their lowest-value waste product.

Through bioremediation using algae and aquatic macrophytes, Algix exploits photosynthesis to capture solar energy and converts the waste water nutrients into biomass that can be used as raw material for composite formulations to make bioplastics. With proper investment in economies of scale, it is believed the material could be a viable option as a cost-competitive, bio-based and thermoformable resin.

After several months of R&D, Dordan HAS successfully thermoformed the algae-plastic, demonstrating the bioresin’s versatility and application to thermoforming.

Algix is located in Georgia, where over 150 carpet plants producing millions of gallons of nutrient-rich waste water are co-located.

Research conducted at the University of Georgia, where Ryan Hunt, director of R&D for Algix is an alumni, has demonstrated high growth rates from various strains of algae and isolated top performing microalgae strains for further development. Algix is in discussions with companies there to scale up biomass production and looks forward to commercialising this new technology. It also has a partnership with Kimberly-Clark.

“To date, few ‘bioresins’ have met the economic and performance requirements of our clients,” said Dordan CEO and president Daniel Slavin. “We are excited about the potential of Algix algae-plastic because it uses industrial waste, as opposed to agricultural by-products, as feedstock – consequently, the debate over using agricultural land to produce the components necessary to synthesize the PLAs and PHAs of the world doesn’t apply, since this technology literally converts waste to biomass.”