FRANKFURT - Ultrasonic welding specialist MS Ultraschall Technologie was at the recent Techtextil exhibition in Frankfurt where it showcased its latest technologies geared towards providing advantages its for the nonwovens processing industry.

As MS Ultraschall notes, quality and reliability are the key to success for nonwovens producers. Considering that the equipment in the nonwovens processing industry often runs 24 hours a day, almost 360 days a year, there is an essential requirement for the high reliability of the components.

The increasing demands from the industry for faster and faster production lines then inevitably leads to technical requirements for maximum mechanical precision, high ultrasonic power and fast process control.

The newly developed ultrasonic generator MS sonxGEN PREMIUM, in connection with the adapted ultrasonic converter, is capable of delivering a continuous output of 3.5 kW. This is significantly more compared to other suppliers. The maximum peak power available is 6 kW.

Oscillating systems with rectangular sonotrodes are available in standardized widths from 85 mm to 270 mm and, depending on the application, can be provided with different coatings for wear protection and to prevent adhesion.

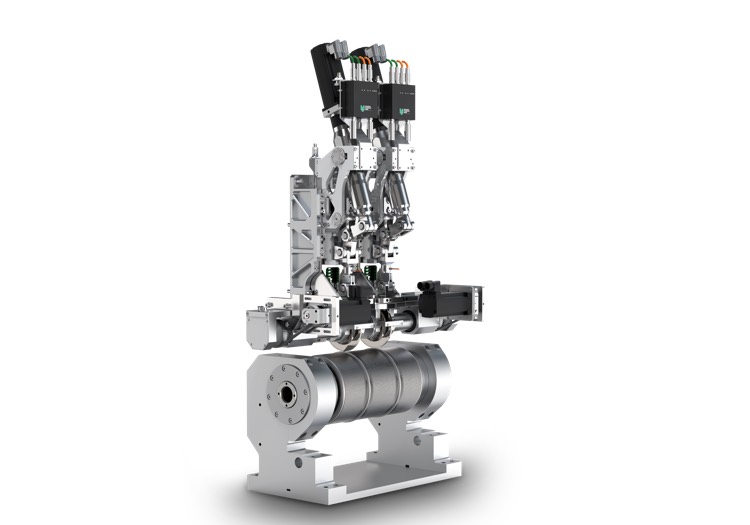

Rotating sonotrodes, which are used in various applications to avoid friction on the nonwoven, are available in 30 kHz and 20 kHz, in widths up to 85 mm and at powers up to 2,000 W (30 kHz) and 3,500W (20 kHz). They offer large welding amplitudes with uniform amplitude distribution over the entire width of the sonotrodes.

The special bearing and guide concept of the servo-electrically driven feed unit offers maximum precision for fast and minimal process adjustments without guide friction at the operating point. The basis for this is a solid-state hinge with fatigue-free CFRP spring elements.

The simple and intuitive operable interface of the control system, which can be used to parameterize and control up to 10 ten systems, offers a wide variety of options for welding process design and control algorithms to adapt to different load cases.

Questions of connectivity, i.e. the simple integration of the systems into superior-level control systems and production data acquisition systems, were the focus of development.

Engraved rolls with complex welding patterns, surface-hardened to increase wear resistance and, if required, vibration-optimized using finite element analysis, enable complete modules to be supplied from a single source. Bale widths of up to 1,000 mm are possible.