TROISDORF - Reifenhäuser Reicofil will be at the upcoming K 2022 exhibition where it will demonstrate how its film-nonwoven mono composites can be a lightweight and recyclable alternative to paper-plastic packaging.

For packaging products to be recyclable, they must primarily be made from only one material. Some emerging packaging trends, such as paper-plastic composites, are therefore not conducive to the circular economy. At K 22, Reifenhäuser will be presenting highly functional, recyclable alternatives in the form of film/nonwoven mono composites.

For bulk material applications, Reifenhäuser Reicofil offers a turnkey line concept that enables customers to produce high-performance nonwoven film composites made of PP mono material and significantly reduce their material consumption: fully recyclable sacks for a variety of free-flowing bulk materials, such as cement, grain or animal feed, can be produced with 25% less material. At the same time, compared to paper-film composites, the barrier effect against moisture increases while at the same time allowing air permeability, which enables air-conveyed filling. The composite can also be used for medical packaging: The material enables steam sterilization of already packaged products.

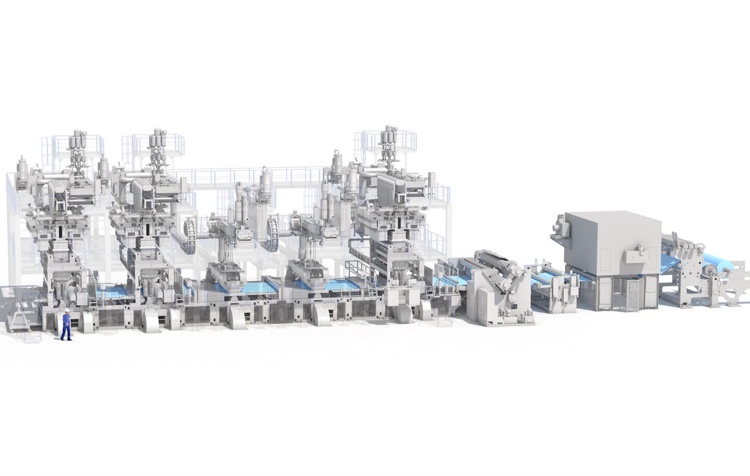

The manufacturing process combines the Reicofil RF5 BiCo spunbond line with an extrusion coating line from sister company Reifenhäuser Cast Sheet Coating. Customers therefore receive a matched solution from a single source. Together with project partner Starlinger, a market leader for machine and process technology for woven plastic sacks, Reicofil also offers a complete turnkey solution including printing unit and sack converting. Together, a production-ready process including the end product - the valve box sack "REICO*STAR" - was successfully introduced to the market.

Dr. Andreas Rösner, responsible for strategic product development at Reifenhäuser Reicofil, explains: "With REICO*STAR and the process behind it, we have shown that nonwoven film composites are a sustainable and economical alternative. They also offer a better moisture barrier and a higher-quality feel than standard paper-film composites. This offers enormous potential to participate in the growing demand for fully recyclable packaging products."

In addition to extrusion coating, laminated nonwoven film composites made of mono-material also offer great potential for more sustainable and visually and haptically appealing packaging.

In cooperation with its sister company Reifenhäuser Blown Film and raw material partner Borealis, Reicofil offers here an overall concept that is also ready for series production and economical for producing nonwovens for mono PP pouches in the area of high-quality food packaging, for example. The nonwoven can be perfectly laminated with flatness-optimized PP blown film to form mono-composites.

The K2022 takes place in October in Duesseldorf. The Reifenhäuser Group will be represented at three of its own booths and one joint booth. The main booth with approximately 1,200 square meters is located in Hall 17 (C 22) and will showcase the Reifenhäuser Blown Film, Cast Sheet Coating and Reicofil business units.