MARKLKOFEN - Filtration specialist Mann+Hummel says that the first vehicles with its new HEPA filter systems will be launched on the market this year, offering the best possible protection against air pollution in the vehicle cabin.

“The term 'HEPA' stands for High Efficiency Particulate Air. The term is not protected, which is why you have to be particularly careful here," said Christoph Krautner, manager development Cabin Air Filter - Particle filtration at Mann+Hummel. "The addition 'according to EN 1822 and ISO 29463' reveals whether the filter actually meets the high demands of European and international standards. Our filters meet these requirements.”

Depending on the HEPA class, at least 99.95% of particles are reliably removed from the air, including harmful bacteria, viruses and other microorganisms, even ultrafine particles (smaller than 0.1 μm). This means that for every 10,000 particles that enter the filter, only up to five particles can pass through the media. “Of particular note here is the performance of HEPA media in the filtration of ultrafine particles such as tire and brake abrasion, and soot. These ultrafine particles are dangerous. Due to their small size, they are capable of transporting toxic compounds to the most vulnerable regions of the body,” Krautner added.

HEPA media have been used in the high-tech industry for many years, for example in the pharmaceutical and healthcare sectors. Mann+Hummel says it has been successfully using HEPA filters in heating, ventilation and air conditioning systems in buildings for several decades. Originally specialized in filter solutions for transport applications, the filter manufacturer uses its experience and highly efficient technology from both sectors to develop cabin air filter systems.

The synthetic HEPA media used by Mann+Hummel consist of several layers of fine fibers and have a significantly lower air permeability than conventional filter media. To achieve the lowest possible pressure drop, the media area of the filter must be increased accordingly. For this reason, a HEPA filter is five times larger than a standard cabin air filter - which explains why one filter cannot replace the other.

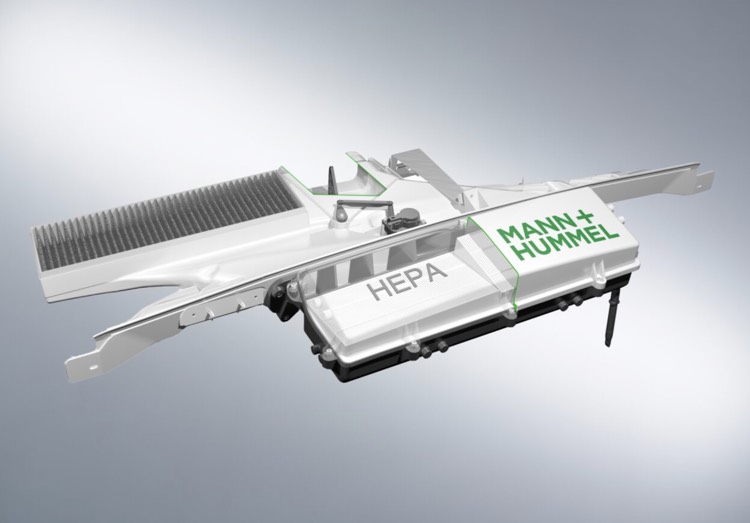

Mann+Hummel combines the HEPA filter with at least one pre-filter, which cleans the outside air of fine dust, pollen as well as pollutants, and therefore puts together a cabin air filter system. To keep the system in a compact size and extend the life of the HEPA filter, the HEPA filter should only be used when it is actually needed. "For effective implementation, we recommend an intelligent system with sensors that monitor air quality and continuously control the system. This ensures that the HEPA filter is automatically activated at the last filtration stage, only when the outside air is extremely polluted, e.g. in a tunnel or traffic jams," recommended Krautner.

Thanks to its intelligent, demand-based fresh air management, the system saves significant energy and helps maximize the range of electric vehicles - benefiting not only the environment, but also the driver. Because fewer charging cycles save vehicle owners time and money.

Systems that contain three filters are optimal: a HEPA filter, a pre-filter and an air conditioning filter. These allow a combination of filter media with different additional functions. For the adsorption of harmful gases and odours, a filter with activated carbon can be used as an option. A bio functional coating for additional inactivation of microorganisms is also suitable.

The cabin air filter system should be placed in a filter housing with a secure sealing concept in front of the heating, ventilation and air conditioning system. Due to their design, electric vehicles are particularly suitable for the installation of such systems.