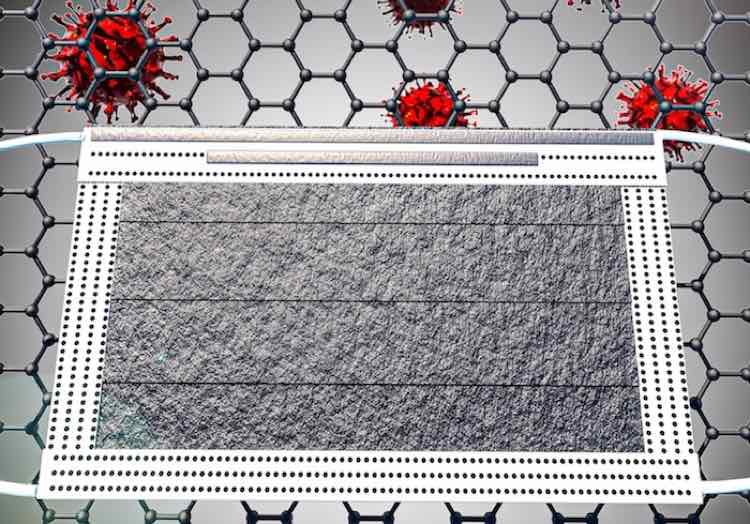

HONG KONG – A graphene coating would make commercially-available nonwoven face masks much easier to sterilize and re-use, according to researchers.

A team at The Hong Kong Polytechnic University (PolyU) have developed a laser manufacturing process that deposits a few layers of the graphene onto the masks to make them superhydrophobic. This reduces the chances of infectious drops adhering to them, while graphene’s strong light-absorption properties make it possible to sterilize them with exposure to sunlight.