AALBORG – The industrial scale production of nanoproducts and advanced filtration media is to commence at Fibertex Nonwovens in Denmark, following a significant investment in new technology.

After more than ten years of research and development and the development of a unique multifunctional production line that is capable of producing a wide range of nano-based nonwoven products, the company is now ready to manufacture unique products for the filtration and medical industries. It has invested in both a new nonwovens production line for filter media and a nanofibre line, to be used in combination with additional value-adding capabilities.

“In the late 2000s, we ran a number of research projects in collaboration with leading universities in the field,” says Fibertex Nonwovens CEO Jørgen Bech Madsen. “Nanotechnology was on everybod’'s lips back then, but so far only a few industries have managed to develop commercially-sustainable products. Still, we have been firm believers all along that nanotechnology could become a game changer in our industry, and we’re now ready for a big-scale market launch of some quite unique products.

“Over the past year, we have been working to establish a state-of-the-art and highly flexible production line at our facility in Denmark that is capable of manufacturing a wide range of products with various nano-based properties.”

In addition to the new production line, which uses a range of polymers such as PU, PVDF and PA which can be tailored for a wide range of different applications, Fibertex Nonwovens has also invested in new lab facilities, new converting and post-processing lines, including plasma treatment, to give the products quite unique and permanently hydrophobic properties.

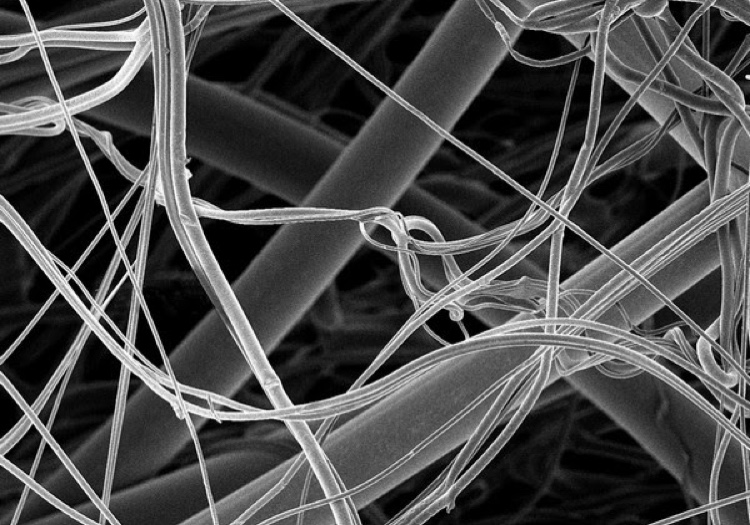

The filtration market is turning out to be one of the most promising markets for Fibertex Nonwovens. The company’s new filtration media offer higher filtration efficiency with less pressure drop than in conventional filtration products. The greater active surface area of the nanofibres and minute deviations in pore size ensure very high filtration material performance. Potential applications for these nano-based filtration products include liquid and air filtration, to filter out bacteria or pollen, for example. The fibres in the nanoproducts have a thickness of only 100 nanometres, whereas ordinary nonwoven fibres are about 100 times thicker.

“We see a huge potential in the filtration market, and our ambition is to become a leading global player capable of manufacturing filters with a wide range of different properties,” says Madesen. “In addition, we have the facilities to produce these products under fully controlled and certified production conditions ensuring environmentally-responsible and sustainable production. All the equipment installed in new premises is fully compliant with the highest environmental and safety standards.”

Web: www.fibertex.com