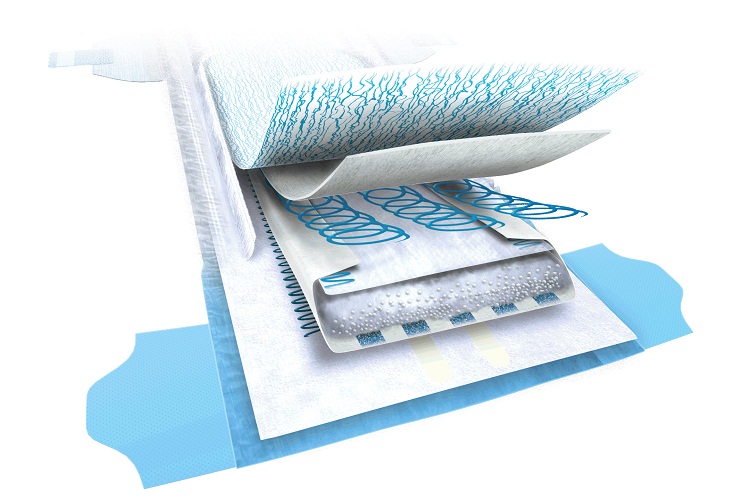

Whatever the combination of components employed, the correct use of adhesives remains critical to the functionality of absorbent cores, says Bostik. Core is a hot topic in today’s disposable hygiene industry– make it thinner, make it more absorbent and keep it from cracking because leaks are bad for business is the mantra. As the list of demands continues to grow, it’s easy to see why manufacturers are researching and experimenting with new core designs to stay competitive. Understanding the key functions of the core system is the first step in meeting user needs and exceeding expectations.