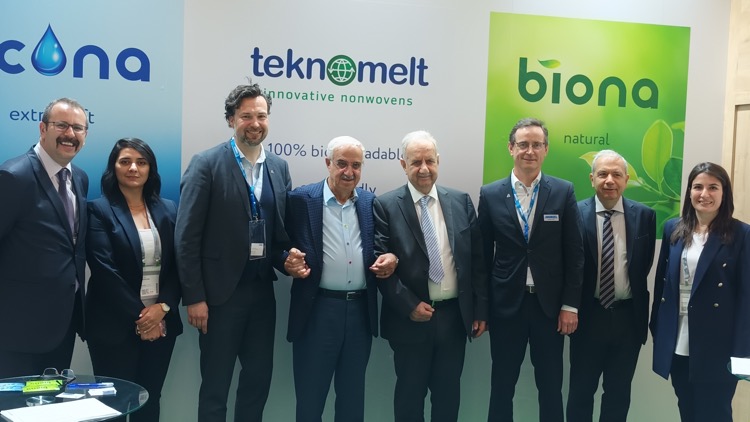

GRAZ - International technology group Andritz has successfully started up a new nonwovens production line supplied to Teknomelt Teknik Mensucat in Turkey.

The new neXline wetlace CCP (carded-carded-pulp) line produces nonwoven roll goods for biodegradable, plastic-free wet wipes.

By combining the benefits of two technologies, spunlace and wetlaid, Andrtiz says the line enables the use of bio-based fibres, like viscose and wood pulp, to produce a high-performance and sustainable wipe with the same technical product characteristics and performances as a conventional wipe made of synthetic fibres while protecting the environment.

Salih Ziya Gümüser, general manager at Teknomelt said this capability “perfectly supports” the company sustainable development goals and opens new growth opportunities.

“With this start-up we have achieved a new milestone in our production,” he said. “Using Andritz’s Wetlace CCP technology, we produce our new Biona fabric brand. Made of viscose and pulp, our Biona fabrics are not only 100% biodegradable but also extra soft and highly absorbent.”

Teknomelt is one of the leading manufacturers of nonwoven meltblown, spunbond, SMS and SMMS fabrics in Turkey. The company serves a wide range of markets, exporting 45% of its production.

With the new Andritz Wetlace CCP line, the company is expanding its range of sustainable nonwovens production for wipes.

Andritz said the start-up of the line also strengthened its strong global position in the supply of production lines for nonwoven roll goods for sustainable wipes.